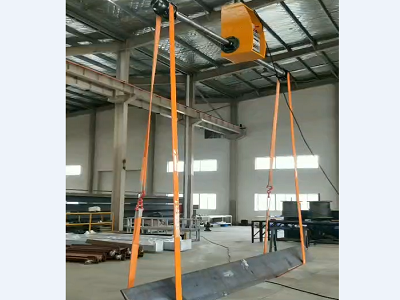

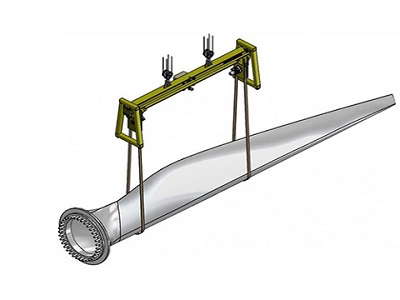

Industrial load turning device is a professional equipment used to flip and adjust the position of heavy workpieces. It is widely used in machinery manufacturing, automobile production, steel structure processing and other industries. The device realizes precise flipping of workpieces through motor drive, hydraulic system or chain drive, and can support 180-degree or 360-degree rotation operation. Industrial load turning device is usually equipped with intelligent control system (such as PLC) and safety protection device to ensure the efficiency and safety of operation. It is especially suitable for flipping irregular or large heavy-loaded workpieces, greatly improving production efficiency and operation convenience.

Main features of industrial load turning device

● Supports 180-degree or 360-degree precise flipping to meet the operation requirements of different workpieces.

● The design structure is sturdy and can carry heavy workpieces from several tons to dozens of tons, suitable for large-scale industrial production.

● Usually equipped with PLC control system, it can realize one-button operation, automatic flipping and precise positioning.

● Suitable for flipping irregular-shaped, large-sized or high-weight workpieces.

● The key components are made of wear-resistant materials, the equipment has a long life, low maintenance requirements and low operating costs.

Application conditions of industrial load turning device

● Automobile manufacturing industry: used for turning operations of chassis, frames and large parts, which is convenient for welding, spraying and assembly, and improves production line efficiency and process quality.

● Metal processing industry: used for turning operations of steel plates, castings, and large structural parts, ensuring that all surfaces of processing can be completed efficiently and reducing errors and risks in manual operations.

● Ship and aviation manufacturing: In the production of hull parts, large cabins or aviation parts, the turning device can safely and efficiently realize multi-angle operation to meet complex process requirements.

● Mechanical manufacturing industry: For turning irregular or large-volume parts (such as turbines, shaft parts, gearboxes, etc.), it is convenient for installation, commissioning and fine processing.

When purchasing an industrial load turning device, you need to consider the following aspects: First, choose the appropriate turning capacity according to the actual working conditions, including load weight, turning angle (whether 360-degree turning is required) and operating frequency; second, pay attention to the compatibility and adaptability of the equipment to ensure that it can meet the turning requirements of specific workpiece shapes and sizes; third, check the safety design of the equipment, including clamping mechanisms, anti-slip devices and emergency stop functions; in addition, give priority to products with PLC control systems to achieve intelligent and precise operation; finally, choose manufacturers with rich experience and perfect services to ensure that the equipment quality, after-sales support and customization capabilities meet the needs.