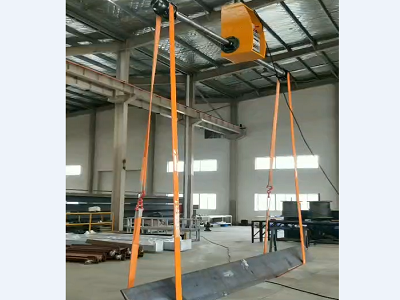

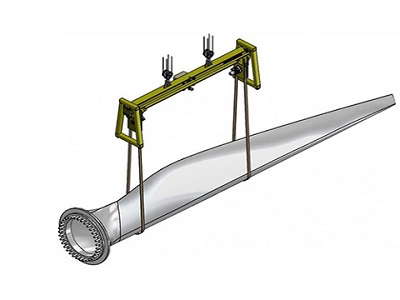

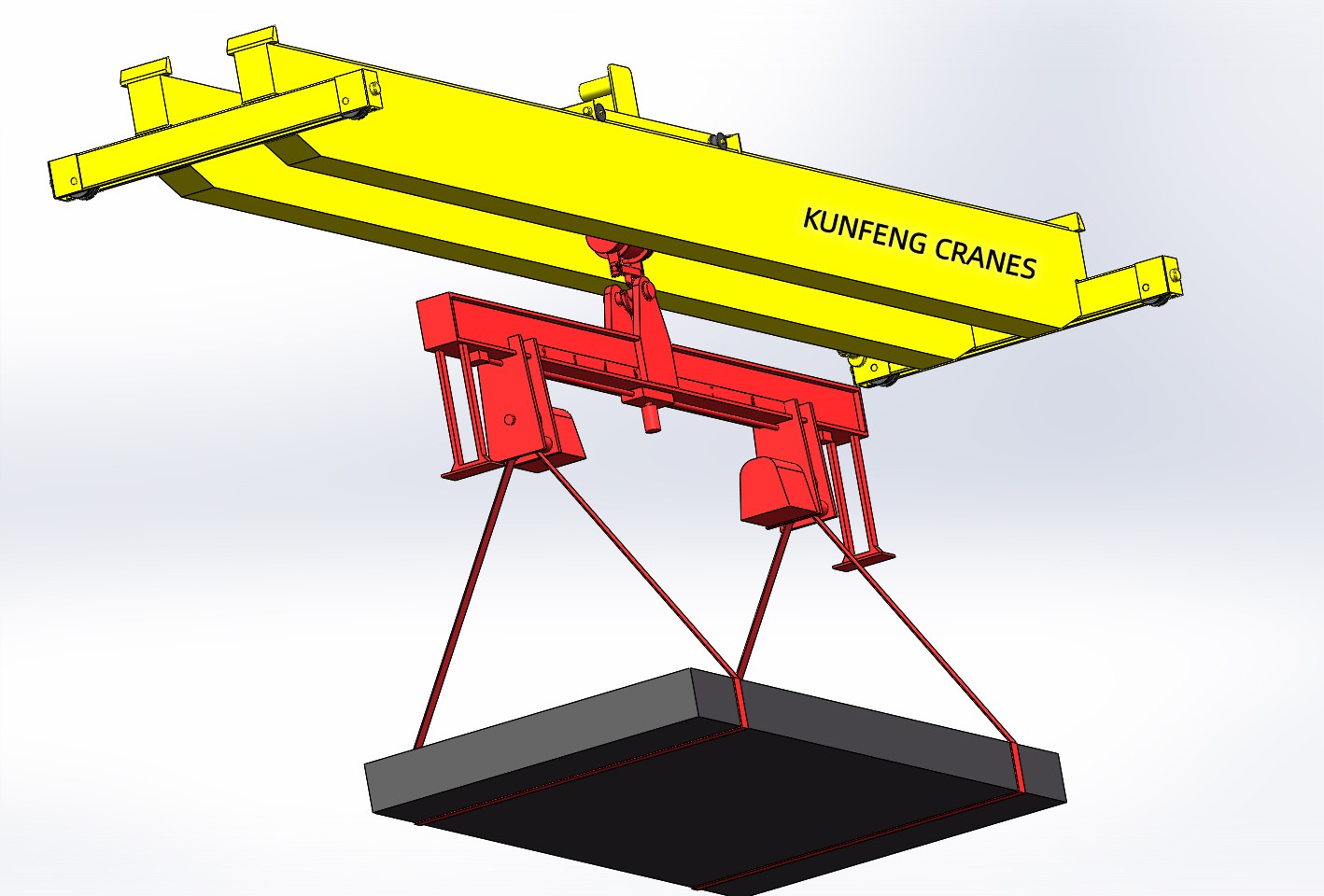

Load turning units are designed for the turning needs of various heavy and special-shaped workpieces and are widely used in mold manufacturing, metal processing, automobile assembly and other industries. The equipment adopts a sturdy structural design and is equipped with an electric, hydraulic or pneumatic drive system. The turning process is smooth and efficient, and supports multi-angle precise operation to ensure the safety and stability of the workpiece during the turning process. The company provides a variety of models and customized options to meet the needs of different working conditions.

Advantages of load turning units

● Made of high-strength materials, it can easily turn heavy workpieces and adapt to a variety of complex working conditions.

● Supports precise turning of 90°, 180° or any angle to meet the diverse needs of various industries for workpiece angle adjustment.

● Equipped with an advanced drive system, it runs smoothly and without impact, significantly improves turning efficiency and reduces the risk of workpiece damage.

● Tailor-made turning devices according to customer needs to support the processing of workpieces of various sizes, shapes and functions.

● Adopting efficient drive technology, the structural design is simple and durable, easy to maintain, and reduces long-term use costs.

Load turning units can be customized according to the specific needs of customers to meet the turning needs of different working conditions and special workpieces. The following are the main steps of the customization process:

● The customer provides specific requirements, including detailed information such as workpiece size, weight, shape, turning angle, and use environment.

● Based on customer needs, the technical team develops a preliminary design plan, including structural design, drive mode (electric, hydraulic or pneumatic), fixture design, etc.

● The preliminary design plan is confirmed with the customer and optimized based on feedback to ensure that the final plan fully meets customer needs.

● The confirmed plan enters the production stage, and the various components of the turning device are manufactured using high-quality materials and advanced processing equipment.

● After manufacturing, the equipment is fully tested, including load testing, turning operation testing, and safety function testing to ensure stable equipment performance and safe operation.

● Deliver equipment according to customer needs, provide installation guidance or on-site installation services to ensure that the equipment is quickly put into use.

● Provide equipment use training, technical support, and subsequent maintenance services to ensure that customers use it without worries.

The load turning units produced by KUNFENG are known for their excellent quality and flexible customization capabilities, and can meet the turning needs of various industries for heavy and special-shaped workpieces. Through a professional design team and perfect after-sales service, we are committed to providing customers with efficient, safe and tailor-made flip solutions and are your reliable partner!