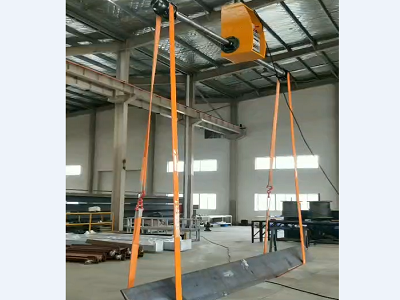

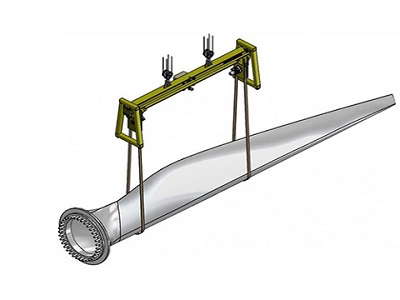

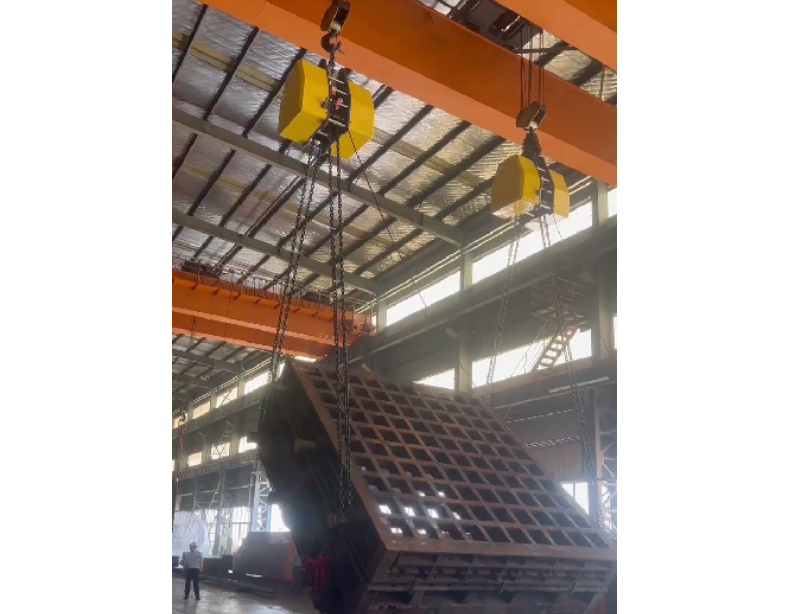

Load rotation equipment can effectively help users complete the tasks of rotating, flipping and moving bulk goods, greatly improving work efficiency and reducing the risks of manual operation. In order to ensure the safety, stability and long-term service life of these equipment, the correct installation steps are essential.

Before starting to install load rotation equipment, a series of preparations must be carried out first:

● Check the equipment and tools: Make sure all installation parts are complete and not damaged. Check the equipment's operating manual to understand the equipment's technical parameters and installation requirements.

● Determine the installation site: Choose a flat, solid ground, and ensure that there is enough space to accommodate the equipment's working range and operating space.

● Clean the work area: The installation area should be cleaned to avoid interference from debris during installation.

● Prepare tools: Prepare installation tools such as wrenches, screwdrivers, levels, lifting tools, etc. according to the requirements of the equipment.

Load rotation equipment usually requires a solid support structure. Before installation, you need to ensure that the infrastructure is stable and meets the design requirements:

● Fix the support frame: Fix the support frame or frame to the ground or other fixed structure according to the design requirements. Use high-strength bolts and welding connections to ensure that the support frame can withstand the equipment's working load.

● Check the level: Use a level to check if the support frame is level. Any uneven support frame will affect the performance and safety of the equipment.

The core component of load rotation equipment is its rotation mechanism. Proper installation of the rotation mechanism is essential to ensure smooth operation of the equipment:

● Install the rotating shaft: Install the rotating shaft into the support structure. Make sure that the connection between the shaft and the support frame is firm and can rotate smoothly. Lubricate the bearings to reduce friction and extend service life.

● Install the rotating motor (if applicable): Some load rotation equipment is equipped with an electric drive system. The motor needs to be installed in the specified position to ensure that the connection between the motor and the rotating shaft is accurate. Check whether the electrical connection of the motor is correct and ensure that the power system meets the specified standards.

● Adjust the rotation angle: Some equipment allows the user to adjust the rotation angle or rotation speed. When installing, ensure that these adjustment mechanisms operate smoothly and test as needed.

The safety of load rotation equipment is very important, especially in environments with high loads and high-speed operations. When installing, the following safety devices should be considered:

● Limit switches: Install limit switches to limit the maximum angle of load rotation to prevent overload operation.

● Overload protection device: Make sure the equipment is equipped with an overload protection system to prevent the equipment from running under overload.

● Emergency stop button: Install an emergency stop button to quickly cut off the power supply of the equipment in an emergency to avoid accidents.

● Safety cover: If the rotating parts of the equipment are exposed, a protective cover should be installed to prevent the operator or other equipment from being injured.

After the installation is completed, it is a crucial step to carry out necessary testing and debugging:

● No-load test: First carry out a no-load test to ensure that all parts of the equipment can operate smoothly. Check whether the electric system, rotating mechanism, adjustment device, etc. are working properly.

● Load test: Carry out a light load test, gradually increase the load, and observe the operation of the equipment. Ensure smooth rotation without abnormal noise or vibration.

● Adjustment operation: Adjust the rotation angle, speed and direction according to actual needs to ensure that the operation of the equipment meets the requirements.

Load rotation equipment through the correct installation steps, you can ensure the safety, stability and efficiency of the equipment. At the same time, regular maintenance and inspection can extend the service life of the equipment and reduce the possibility of failure. During the installation process, always follow the recommendations and safety regulations in the equipment manual, and consult professionals when necessary.