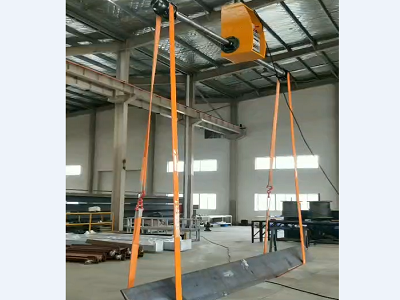

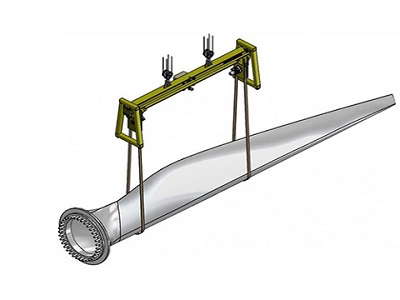

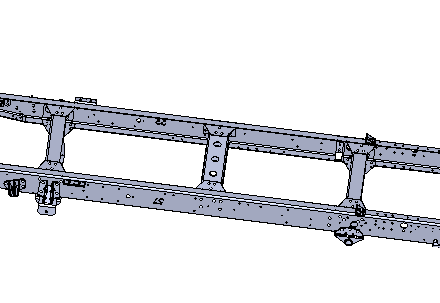

KUNFENG chassis load rotator is a high-efficiency equipment designed for automobile manufacturing, maintenance and other fields. It is made of high-strength steel, has excellent stability and durability, and can easily carry the weight of various types of automobile chassis. Its unique flipping mechanism design is extremely easy to operate. Through the electric control system, it can achieve a smooth, fast and accurate 180 degree flip, which greatly facilitates workers to assemble, inspect, repair and clean the chassis.

Importance of choosing a belt load rotator

The belt has good flexibility and elasticity. During the power transmission process, it can effectively buffer the impact generated during the start-up and operation of the motor, thereby reducing damage to the entire flipper structure and extending the service life of the equipment. The belt drive runs smoothly and has low noise, which is extremely important for workshops that require a quiet working environment. It can reduce noise pollution and create a more comfortable working atmosphere for workers. The installation and maintenance of the belt load rotator are relatively simple and low-cost. While ensuring efficient transmission, it can effectively control the overall cost of the equipment.

Safe operation of chassis load rotator

Load capacity inspection

● The load capacity of the equipment should be checked before each use to ensure that it matches the weight of the chassis to be transported.

Equipment installation and stability

● Before operation, make sure that the support arm and rotating platform of the rotator are firmly locked to prevent looseness or instability during rotation.

Operator training and certification

● Only certified personnel can perform chassis turning operations to ensure standardized operation and avoid safety accidents caused by improper operation.

Safety control during turning

● The start and stop of the load rotator should be smooth, avoiding violent acceleration or emergency stop, which helps prevent the load from becoming unstable during the turning process and damage to the equipment and chassis.

Safety protection device

● Equipped with a limit device to ensure that the turning angle does not exceed the safe range to prevent the load from falling or other safety hazards.

Equipment inspection and maintenance

● The moving parts of the turning machine should be cleaned and lubricated regularly to reduce wear and ensure smooth operation of the equipment.

We are equipped with multiple safety protection devices when designing the load rotator, from automatic detection before starting to overload protection during operation, to fully protect the safety of operators. Whether it is an automobile manufacturing workshop, aerospace field, or mechanical processing industry, choosing our load turning device means choosing higher production efficiency and more reliable safety guarantee.