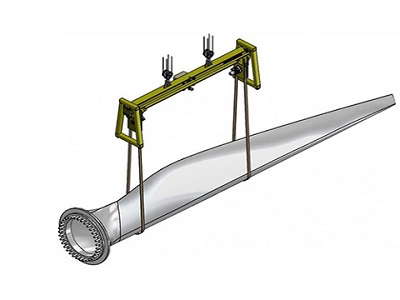

Twin hoist turning device is a device that uses two hoist systems to work together to turn heavy objects. It is usually used in situations where large and heavy objects need to be turned. The device controls both sides of the load through two hoists, which can achieve balanced lifting and precise turning of the load. It is widely used in heavy components or chassis rotating in industries such as automobiles, aviation, and machinery manufacturing. When working, the two hoists can apply pulling or lifting force from different positions of the object according to the set program or the operator's instructions, so as to achieve efficient, accurate, safe and stable turning of the object in space.

Design features of twin hoist turning device

● The two independent hoist systems work together to ensure that the lifting of both ends of the load is synchronized to avoid tilting or imbalance during the turning process.

● It can carry higher weights and loads and is suitable for turning large and heavy objects.

● The lifting speed and turning angle can be adjusted as needed to ensure a smooth and controllable turning process.

● Equipped with overload protection, limit devices and emergency stop devices, it can prevent overload operation and stop the equipment operation in time when a fault occurs.

● The equipment is easy to maintain and maintain, reducing the operating and maintenance costs.

Process of customizing twin hoist turning device

● Communicate with customers in detail to understand their specific needs, including load weight, turning angle, use environment (such as clean room, workshop, outdoor, etc.), working frequency, and specific safety requirements.

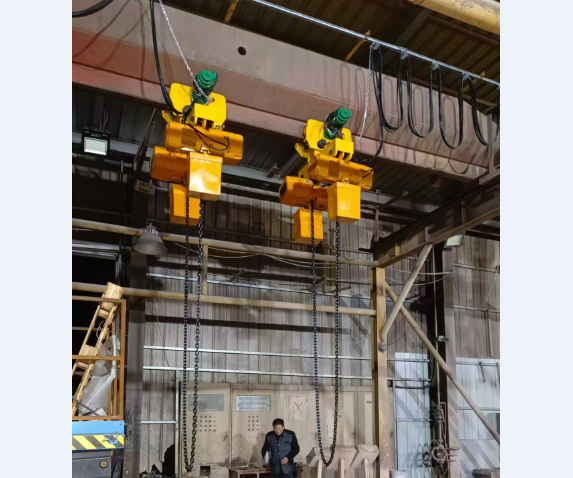

● Engineers make preliminary designs based on customer needs and technical specifications. The design content includes the layout plan of the twin hoist system, structural drawings, electronic control system design, lifting mechanism, turning control system, etc.

● According to the design drawings and technical requirements, purchase high-quality materials such as high-strength steel, hydraulic system components, electronic control components, etc.

● Assemble and weld the processed parts to ensure the stability of the structure and ensure that the turning device can withstand the predetermined load and use conditions.

● Test the synchronization of the twin hoist system to ensure that the two hoists can work in a coordinated manner, and the load can be lifted and lowered smoothly during the turning process to avoid imbalance.

● Arrange equipment transportation according to customer needs, and provide on-site installation and commissioning services to ensure the smooth operation of the equipment.

As a manufacturer of customized load turning device, KUNFENG ensures that the turning device produced can meet the specific needs of customers and provide a safe, efficient and stable use experience through full communication with customers, precise design and strict testing. Welcome to contact us for free design solutions and preferential quotations!