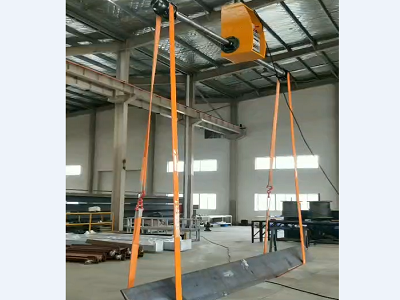

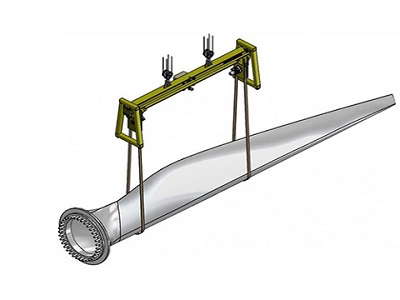

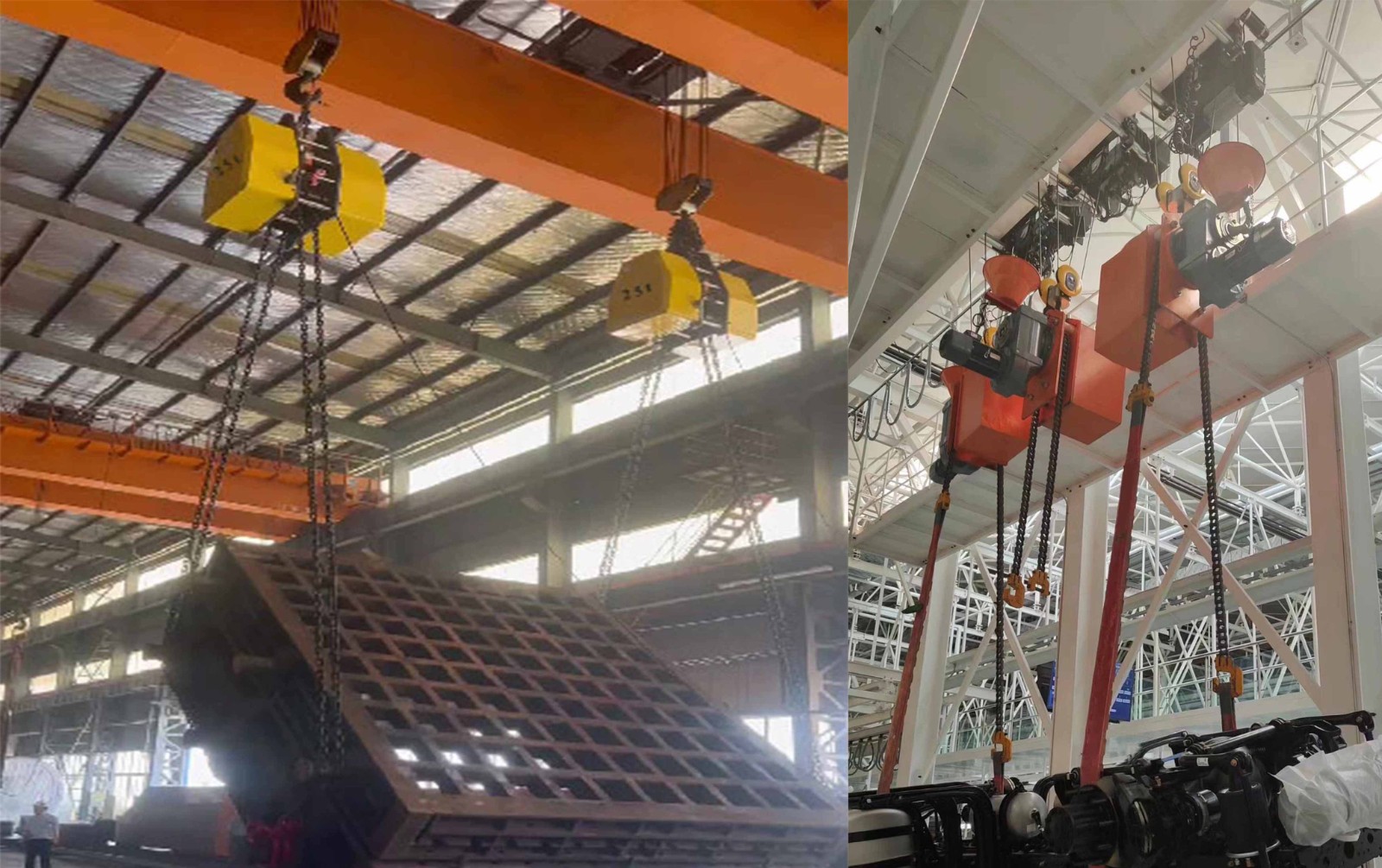

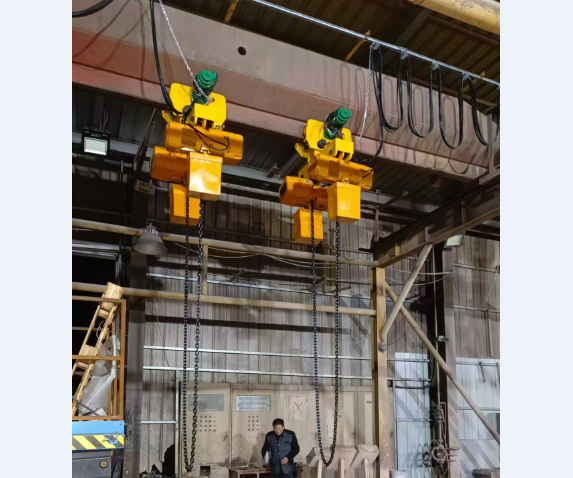

The load turning devices we produce can achieve smooth turning of workpieces, accurately control the turning angle, and ensure safe and stable operation. Whether it is large mechanical parts, metal structures or other heavy materials, turning devices can provide reliable support. Its high load capacity and sturdy structural design ensure stable operation even under harsh working conditions. The automation and intelligent control system of the equipment make operation easier, greatly improve production efficiency and reduce labor intensity.

Advantages of load turning devices

● Adopting high-strength materials and precision manufacturing processes, it can carry large and heavy workpieces and ensure stable operation under harsh working conditions.

● Integrated intelligent control system supports automated operation, remote control and precise adjustment, which greatly improves the efficiency and accuracy of the turning process.

● Reduces the labor intensity caused by traditional manual turning, and reduces the error of human operation through automated control.

● Adopting high-quality materials and wear-resistant design, ensure that the equipment can still maintain efficient operation under long-term high-load work.

● The turning device is compact and flexible in design, suitable for use in space-constrained working environments.

Application industries and scenarios of load turning devices

Manufacturing

● Machining: used to turn the workpiece to different angles for welding, processing, inspection or assembly. Especially for large mechanical parts and workpieces with complex shapes, turning devices can improve processing accuracy and efficiency.

● Mold manufacturing: used for turning and replacing molds to ensure the smooth progress of different processes in the mold processing and reduce manual intervention.

Steel and metallurgical industry

● Casting and forging turning: can be used to turn heavy castings or forgings to make them easier to cool, inspect, process or assemble.

● Steel structure turning: used to turn steel structure parts to the appropriate angle for welding or assembly.

Automobile manufacturing

● Automobile body turning: can be used to turn the body or frame for welding, painting and other assembly processes.

● Large automobile parts turning: turning heavy parts such as engines, wheels or chassis helps to improve assembly efficiency and reduce manual operations.

Shipbuilding and repair

● Hull component turning: used to turn hull components or other heavy structural parts to ensure that they reach the appropriate posture and angle during construction or repair.

● Ship equipment turning: used to turn large mechanical equipment and ship accessories for subsequent installation and maintenance.

The application of load turning devices covers many industries, especially in places where the workpiece needs to be turned or adjusted during handling, assembly, processing and welding. Through automation and intelligent control, turning devices can improve production efficiency, ensure operational safety and reduce labor intensity, becoming an indispensable and important equipment in modern industrial production.