Moving or rotating large objects on a factory floor can be a very difficult task. The loads are often too heavy for existing workers to handle, and an accidental drop can have disastrous consequences. But by using the right load turning device, the job becomes easier, improving safety, increasing productivity, and bringing other benefits.

Types of load turning device

Chain load turning device

● Uses high-strength chains for lifting and turning, suitable for carrying heavy workpieces.

● Compact structure, smooth turning process, and 360-degree continuous rotation.

● Flexible operation, equipped with intelligent control system, can accurately control the turning angle.

● Widely used in metal processing, mold manufacturing and large casting turning scenarios.

Electric turning device

● The workpiece is turned by an electric drive system, which is simple to operate and efficient.

● The turning process is programmable and supports automated production line integration.

● Low energy consumption, easy maintenance, suitable for small and medium-sized load workpieces.

● Widely used in electronic manufacturing, precision machinery assembly and light industry.

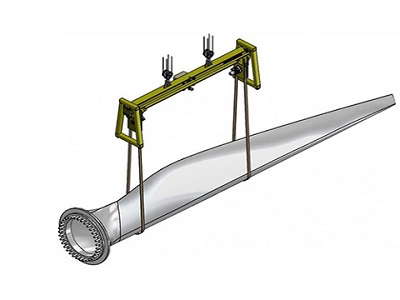

Suspended load turning device

● The workpiece is turned through a suspension system, usually with a crane or lifting equipment.

● It takes up little space and is suitable for scenes where lifting and turning are combined.

● It can be used for workpiece operations in clean environments or narrow spaces.

Enterprises can choose the appropriate turning device type based on the specific workpiece type, load requirements, operating environment, and production line requirements to maximize production efficiency and ensure the safety and stability of operations. Contact KUNFENG CRANES now to get a free customized solution to meet your manufacturing needs.