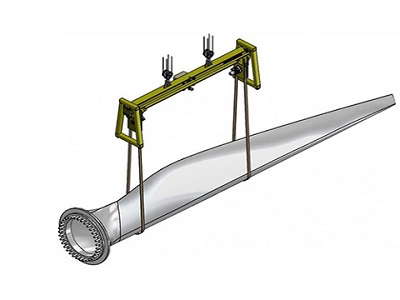

The mobile gantry load turning device adopts a sturdy gantry structure with excellent load-bearing capacity, which can easily handle all kinds of large and heavy loads. The unique mobile design, equipped with high-performance rollers and advanced drive systems, can be flexibly moved in workshops and other work sites to meet the needs of different working positions. Through the precise electric control system, the load can be turned smoothly and safely, and the turning angle can be flexibly adjusted to meet the needs of different working conditions.

Advantages of mobile gantry load turning device

High load-bearing capacity

● The sturdy gantry structure has a large span and load-bearing capacity, which can support the turning of heavy objects (such as car chassis, mechanical parts, etc.).

Flexibility and mobility

● The device has flexible movement functions and can change working positions at any time in the workshop. The mobile wheel or track system installed at the bottom of the device can easily realize the rapid transfer of the equipment between production lines or different working areas.

Accurate turning control

● The device adopts an electric drive system, which can achieve smooth lifting and precise turning of the load. During the turning process, it can ensure that the load is stable and not prone to tilting or uneven distribution.

Easy to operate

● Operators can easily lift, flip and move the load with simple buttons or remote control operations, which improves operating efficiency and reduces labor burden.

Strong adaptability

● It can be customized according to different working environments and needs, and can adapt to a variety of load types and flip angles. It is widely used in chassis flipping, component handling, assembly and other scenes in the automotive, machinery, aviation and other industries.

Mobile gantry load turning device is widely used in industries such as automobile manufacturing, mechanical processing, heavy equipment maintenance and aerospace. It is particularly suitable for work scenes that require flipping, handling and adjusting large objects, such as assembly and testing of chassis, mechanical parts and large structural parts. Due to its flexible mobility, it can move freely in the workshop and adjust the working position according to different needs, so it performs well in material transfer and flipping operations between multiple stations.