- +86 13390692151

- sale@kfqizhongji.com

- Mon - Sat 8:00 - 17:30, Sunday - CLOSED

-

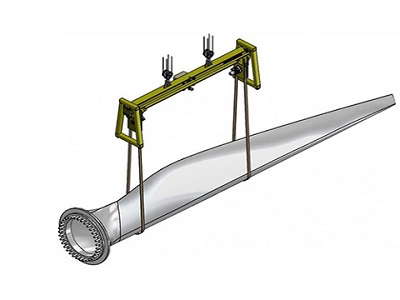

Turnover Spreader Beams for Rotating Heavy Loads

-

180 Degree Load Rotation Equipment

-

Load Turning Units for Irregular Workpieces

-

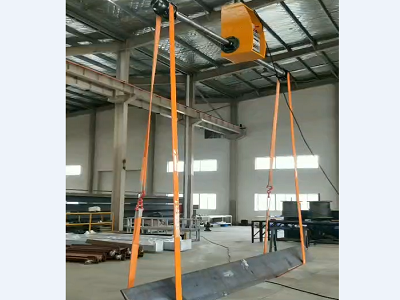

Textile Lifting Slings Turning Device

-

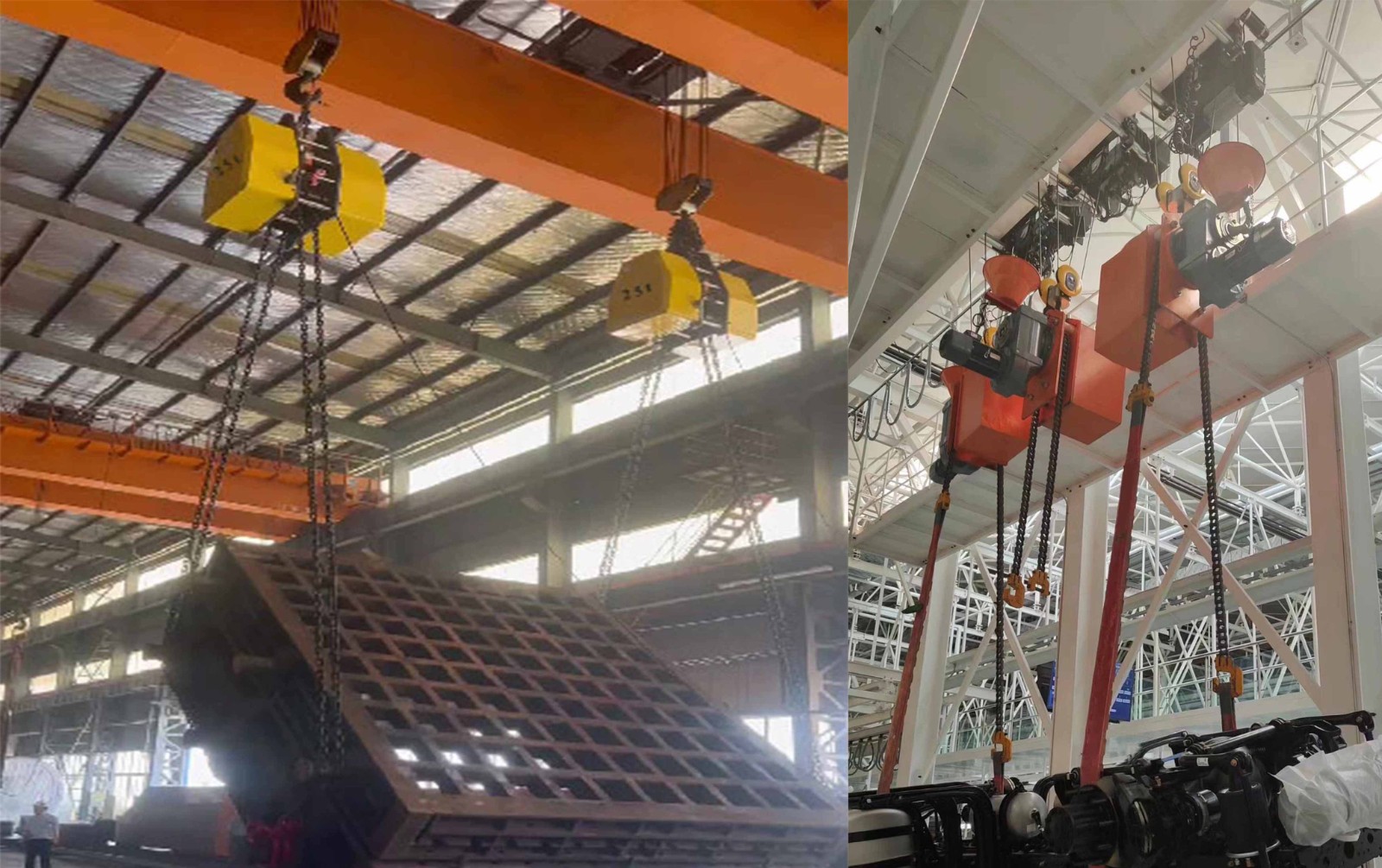

Chain Load Turning Beam

-

Load Turning Crane Attachment

-

Belt Load Turning Crane Hook

-

Diesel Forklift Chassis Rotator

-

Electric Suspended Load Turner

-

Fixed Belt Load Turning Device

Load Turning Devices

Category: Load Turning Device

Load turning devices are industrial equipment used to adjust the angle or flip the position of heavy or special-shaped workpieces. They can flip the workpiece from a horizontal position to a vertical position, or achieve a complete 180° and 360° flip.

Email:sale@kfqizhongji.com

Contact Us For QuotationLoad turning devices are industrial equipment used to adjust the angle or flip the position of heavy or special-shaped workpieces. They are widely used in manufacturing, mold flipping, automobile frames and chassis, etc. It uses motor, hydraulic or pneumatic drive, combined with clamping or supporting mechanisms, to flip the workpiece from horizontal to vertical position, or achieve a complete 180° and 360° flip. Load turning devices have the characteristics of high load capacity, smooth operation and precise control, which can significantly improve work efficiency and ensure the safety of workpiece handling process. They are indispensable and important auxiliary equipment in modern industry.

Features of load turning devices

● The design is sturdy and durable, capable of handling flips from light materials to ultra-heavy equipment, and adapting to various industrial load requirements.

● It supports multi-angle precise flipping of workpieces, and can achieve flexible adjustment from horizontal to vertical or other specified angles to meet diverse operating requirements.

● Equipped with safety functions such as anti-slip clamps, overload protection, and limit devices to effectively ensure the safety of operators and equipment.

● It supports integration with production lines or industrial robots to achieve automated operations and meet the needs of modern intelligent manufacturing.

● Some models use energy-saving drive systems, with low operating noise and low energy consumption, which meets the requirements of green production.

Application conditions of load turning devices

● Mold manufacturing and processing: used for flipping and angle adjustment of large molds, which is convenient for cleaning, assembly and maintenance of molds.

● Metal processing industry: flip steel plates, aluminum plates or other metal workpieces to facilitate cutting, welding, grinding or spraying and other processing processes.

● Automotive manufacturing industry: used for flipping automotive parts (such as chassis, frame, etc.) to facilitate welding, painting or assembly processes.

● Wind power and energy industry: flip wind power equipment components (such as blades, cabins, etc.) or energy equipment parts to facilitate construction and installation.

● Warehousing and logistics industry: flip boxes, pallets or goods to meet the loading, unloading, sorting and handling needs in logistics warehousing.

The load turning devices produced by KUNFENG CRANES provide efficient and safe workpiece flipping solutions for various industries with excellent performance and reliability. The equipment is designed to be sturdy and durable, supports multi-angle precise flipping, and can easily cope with the processing needs of heavy, special-shaped or fragile workpieces. Whether it is mold processing, metal manufacturing, warehousing logistics, or the automotive, electronics and energy fields, our flipping devices can significantly improve operating efficiency and optimize production processes. Contact us for free to provide customized solutions that meet your needs and reasonable and preferential quotes!

Recommend Cases

Recommend News

- 2025-01-17 Advantages of Mobile Gantry Load Turning Device

- 2025-01-09 Operation of Heavy Duty Car Frame Turning Device

- 2025-02-07 Application Scenarios of The Turning Device on Crane Hook

- 2025-01-24 How to Keep Balance on Chain Turning Device

- 2025-03-05 Operating Guide for Chain Load Turning Device in Foundry

- 2024-12-03 Belt Load Turning Units with Automatic Balancing Function

- 2025-02-13 Turning Device of Loading and Rotating Conveyors

- 2024-12-27 What Maintenance Does an Industrial Load Turner Require

- 2025-01-13 Design Features of Electric Load Turning Device

- 2024-12-03 How Belt Load Rotator Turns Over Truck Chassis