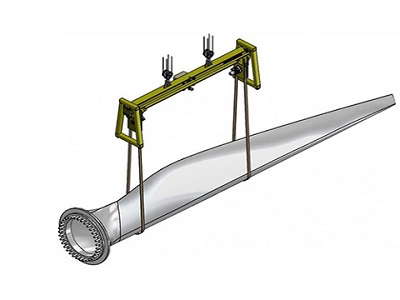

Heavy duty turning device is widely used in automobile manufacturing, heavy machinery assembly and other production environments that require processing of large-sized and heavy workpieces. The device can smoothly turn large workpieces such as heavy duty car frames from one position to another angle through a strong drive system and a precise turning mechanism, ensuring that the workpiece will not tilt or be damaged during the turning process. On the automobile production line, it is usually used in processes such as welding, painting and assembly of the frame, helping workers to efficiently perform multi-angle operations, improve production efficiency and operational safety.

Safe operation of heavy duty rotator turning device

Equipment inspection and maintenance

● Before each use, a comprehensive inspection of the equipment should be carried out, including the driving system, support frame, turning belt, control system, etc. of the turning device to ensure that all components are working properly. Regular inspection and maintenance can effectively avoid equipment failure, reduce the risk of accidents, and ensure a smooth and stable turning process.

Load limit

● Operate strictly in accordance with the maximum load standard of the equipment and do not overload it. Overload operation will cause the equipment to lose control, and may even cause equipment damage or turning failure, increasing the risk of worker injury.

Operator training

● All operators must undergo professional training to master the correct use of the turning device, emergency stop operation and troubleshooting skills. Trained operators can master the operation of the equipment, reduce human errors, and ensure safe operation.

Preparation before turning

● Before starting the turning operation, ensure that the workpiece is firmly placed on the turning bracket and all connecting devices (such as turning belts, brackets, etc.) are firmly fixed. If the workpiece is not firmly placed or the turning bracket is unstable, it will cause the workpiece to slip during the turning process, causing damage or personal injury.

Control system and emergency stop

● Equipped with a reliable control system, including start and stop buttons, speed adjustment and emergency stop devices, it can monitor the turning status in real time to ensure a smooth turning process.

Monitoring during the turning process

● The operator should monitor the turning progress throughout the process to ensure that the workpiece turns stably at the set angle and speed. It helps to detect abnormal conditions in time, such as unstable workpieces or equipment failures, and take quick measures.

Complying with the safe operating specifications of the car frame turning device can not only ensure the long-term stable operation of the equipment, but also effectively reduce accidents caused by improper operation or environmental factors, ensure the safety of workers and improve work efficiency. Welcome to contact us to customize the turning equipment to meet your needs.