- WhatsApp: +86 13390692151

- sale@kfqizhongji.com

- Mon - Sat 8:00 - 17:30, Sunday - CLOSED

-

Belt Single Sling Load Rotator

-

Load Turning Units for Irregular Workpieces

-

Turnover Spreader Beam with Electric Adjustable Units

-

Chassis Flip Device with PLC Control System

-

Electric Suspended Load Turner

-

Load Turning Units Suspended From Cranes

-

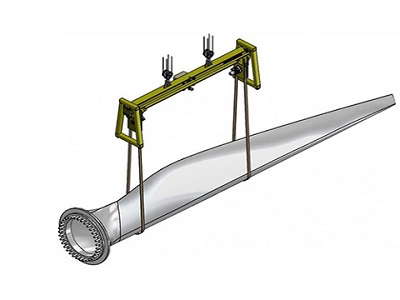

Wind Turbine Blade Lifting and Turning Device

-

Load Turning Crane Attachment

-

Electric Powered Rotators for Welding Workpieces

-

Casting Mold Chain Turning Device

Belt Electric Load Rotator

Category: Load Turning Device

Belt electric load rotator adopts electric drive and high-strength fiber belt design, which can turn heavy equipment or workpieces and realize the rotation and positioning of materials at various angles.

Email:sale@kfqizhongji.com

Contact Us For QuotationThe belt electric load rotator is an intelligent device designed for heavy equipment or workpiece flipping. It combines a strong industrial belt with an electric control system to achieve precise flipping and rotation of large-sized or irregular-shaped workpieces. The device is usually equipped with a programmable logic controller (PLC) system, which can set the flip angle and speed according to demand to ensure smooth and efficient operation. It is widely used in automobile manufacturing, mechanical processing, wind turbine blade production and other fields. It has the advantages of convenient operation, uniform load, and no damage to the workpiece surface. It is an important tool for improving efficiency in modern industrial production.

Main components of the belt electric load rotator

● Drive system: Usually composed of a motor and a reducer, which provides power to the rotator and controls the flip speed and direction to ensure a smooth flipping process.

● Industrial belt: A high-strength, wear-resistant industrial belt is used to carry and fix the workpiece. The industrial belt is flexible and tensile-resistant, and can effectively protect the workpiece surface from damage.

● Support frame: Made of high-strength steel or aluminum alloy, it provides structural support and stability. The frame design is compact and durable, suitable for different working conditions.

● Control system: equipped with PLC controller and operation panel, supports accurate setting of parameters such as flip angle and speed, and some high-end equipment supports remote control or integration with intelligent production lines.

● Rotation device: responsible for realizing 360-degree rotation of the load, usually composed of rollers or bearing groups to ensure smooth rotation without jamming.

Advantages of belt electric load rotator

● Achieve 360-degree free rotation and flipping, suitable for a variety of workpiece shapes and sizes, and improve work efficiency.

● Equipped with PLC control system, the flip angle and speed can be set to ensure accurate operation and consistency of process requirements.

● Flexible industrial belts are used to effectively reduce surface damage of workpieces, suitable for scenes with high requirements for surface quality.

● Lightweight design, small footprint, suitable for a variety of production environments.

● Adopting high-efficiency motor drive, low energy consumption, low operating noise, in line with modern industrial environmental protection requirements.

Belt electric load rotator is widely used in various industrial conditions where workpieces need to be flipped and rotated, especially for scenes with high requirements for workpiece surface or complex shapes. Common applications include welding, assembly and inspection processes in mechanical manufacturing, frame and chassis turning in the automotive industry, large component turning in the heavy equipment industry, and efficient and safe turning of precision parts in the aerospace field. If you need to purchase load turning device, please contact us as soon as possible to provide you with the best workpiece turning solution!

Recommend Cases

Recommend News

- 2024-12-03 Belt Load Turning Units with Automatic Balancing Function

- 2025-10-10 Design of Double Chain Synchronous Drive Load Rotator

- 2025-06-18 How to Choose The Right Load Turning Device

- 2025-12-03 Crane Turning Device for Rotating Engine Blocks

- 2025-01-17 Advantages of Mobile Gantry Load Turning Device

- 2025-10-22 A Comprehensive Guide on How to Buy Rotator Turning Device

- 2025-05-26 Turning Device Installed on Crane Lifting Beam

- 2025-11-11 Design Features of Electric Load Turning Device

- 2024-12-27 What Are The Application Scenarios of Load Turning Devices

- 2025-01-24 How to Keep Balance on Chain Turning Device